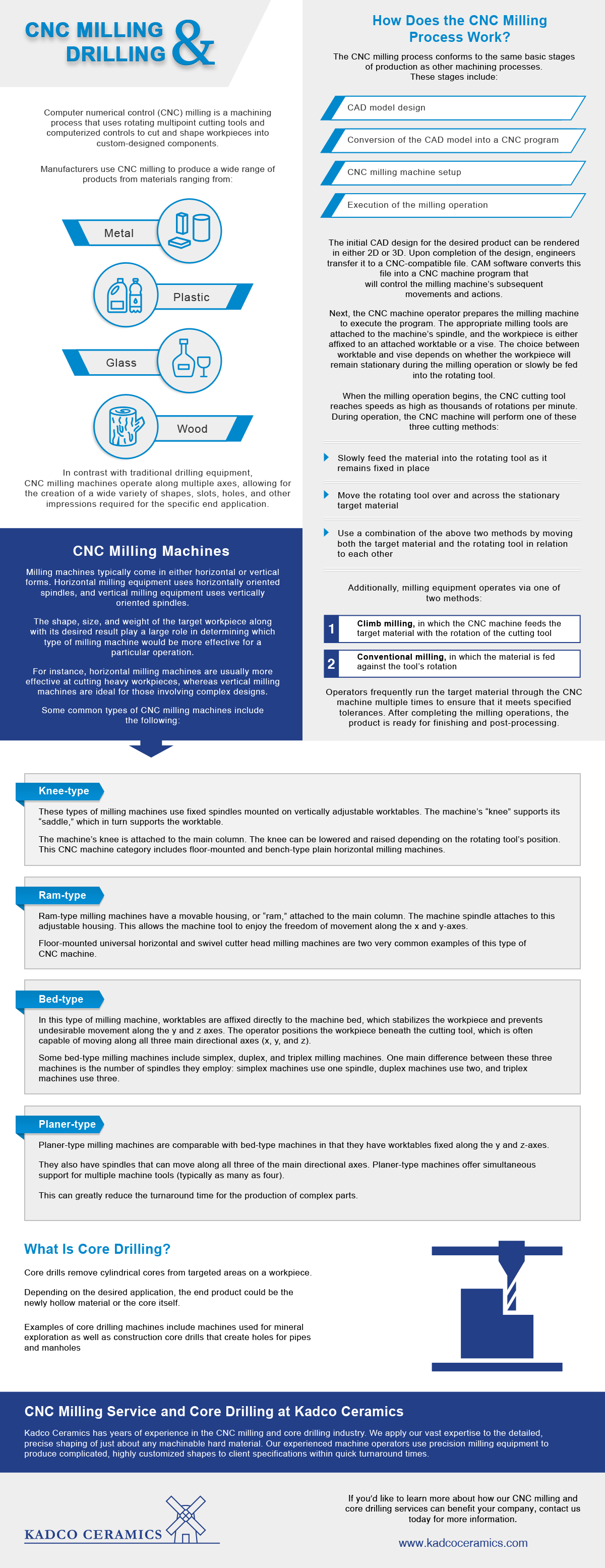

Computer numerical control (CNC) milling is a machining process that uses rotating multipoint cutting tools and computerized controls to cut and shape workpieces into custom-designed components.

Manufacturers use CNC milling to produce a wide range of products from materials ranging from:

- Metal

- Plastic

- Glass

- Wood

In contrast with traditional drilling equipment, CNC milling machines operate along multiple axes, allowing for the creation of a wide variety of shapes, slots, holes, and other impressions required for the specific end application.

How Does the CNC Milling Process Work?

The CNC milling process conforms to the same basic stages of production as other machining processes. These stages include:

- CAD model design

- Conversion of the CAD model into a CNC program

- CNC milling machine setup

- Execution of the milling operation

The initial CAD design for the desired product can be rendered in either 2D or 3D. Upon completion of the design, engineers transfer it to a CNC-compatible file. CAM software converts this file into a CNC machine program that will control the milling machine’s subsequent movements and actions.

Next, the CNC machine operator prepares the milling machine to execute the program. The appropriate milling tools are attached to the machine’s spindle, and the workpiece is either affixed to an attached worktable or a vise. The choice between worktable and vise depends on whether the workpiece will remain stationary during the milling operation or slowly be fed into the rotating tool.

When the milling operation begins, the CNC cutting tool reaches speeds as high as thousands of rotations per minute. During operation, the CNC machine will perform one of these three cutting methods:

- Slowly feed the material into the rotating tool as it remains fixed in place

- Move the rotating tool over and across the stationary target material

- Use a combination of the above two methods by moving both the target material and the rotating tool in relation to each other

Additionally, milling equipment operates via one of two methods:

- Climb milling, in which the CNC machine feeds the target material with the rotation of the cutting tool

- Conventional milling, in which the material is fed against the tool’s rotation

Operators frequently run the target material through the CNC machine multiple times to ensure that it meets specified tolerances. After completing the milling operations, the product is ready for finishing and post-processing.

CNC Milling Machines

Milling machines typically come in either horizontal or vertical forms. Horizontal milling equipment uses horizontally oriented spindles, and vertical milling equipment uses vertically oriented spindles.

The shape, size, and weight of the target workpiece along with its desired result play a large role in determining which type of milling machine would be more effective for a particular operation.

For instance, horizontal milling machines are usually more effective at cutting heavy workpieces, whereas vertical milling machines are ideal for those involving complex designs.

Some common types of CNC milling machines include the following:

Knee-type

These types of milling machines use fixed spindles mounted on vertically adjustable worktables. The machine’s “knee” supports its “saddle,” which in turn supports the worktable.

The machine’s knee is attached to the main column. The knee can be lowered and raised depending on the rotating tool’s position. This CNC machine category includes floor-mounted and bench-type plain horizontal milling machines.

Ram-type

Ram-type milling machines have a movable housing, or “ram,” attached to the main column. The machine spindle attaches to this adjustable housing. This allows the machine tool to enjoy the freedom of movement along the x and y-axes.

Floor-mounted universal horizontal and swivel cutter head milling machines are two very common examples of this type of CNC machine.

Bed-type

In this type of milling machine, worktables are affixed directly to the machine bed, which stabilizes the workpiece and prevents undesirable movement along the y and z axes. The operator positions the workpiece beneath the cutting tool, which is often capable of moving along all three main directional axes (x, y, and z).

Some bed-type milling machines include simplex, duplex, and triplex milling machines. One main difference between these three machines is the number of spindles they employ: simplex machines use one spindle, duplex machines use two, and triplex machines use three.

Planer-type

Planer-type milling machines are comparable with bed-type machines in that they have worktables fixed along the y and z-axes.

They also have spindles that can move along all three of the main directional axes. Planer-type machines offer simultaneous support for multiple machine tools (typically as many as four).

This can greatly reduce the turnaround time for the production of complex parts.

Best Materials for CNC Milling

CNC milling is a versatile manufacturing process that encompasses the use of a variety of materials. The best material to use for a specific order depends on the desired end application of the product.

Some of the harder materials suitable for CNC milling include:

- Alumina: Alumina comes in different varieties. Producers use 99.6% alumina for thin-film microwave circuits that operate at higher frequencies. 92% alumina is effective for packaging applications.

- Garnet: Garnets are extremely hard metal silicates. They see use in the electronics and optics fields.

- LiNbO3: LiNbO3 is a dense synthetic crystal used for photonics applications.

- Tungsten: Tungsten is a hard metal that works well in electronic applications.

What Is Core Drilling?

Core drills remove cylindrical cores from targeted areas on a workpiece. Depending on the desired application, the end product could be the newly hollow material or the core itself.

Examples of core drilling machines include machines used for mineral exploration as well as construction core drills that create holes for pipes and manholes.

CNC Milling Service and Core Drilling at Kadco Ceramics

Kadco Ceramics has years of experience in the CNC milling and core drilling industry. We apply our vast expertise to the detailed, precise shaping of just about any machinable hard material. Our experienced machine operators use precision milling equipment to produce complicated, highly customized shapes to client specifications within quick turnaround times.

If you’d like to learn more about how our CNC milling and core drilling services can benefit your company, contact us today for more information.

Thomas Registered Supplier

Thomas Registered Supplier