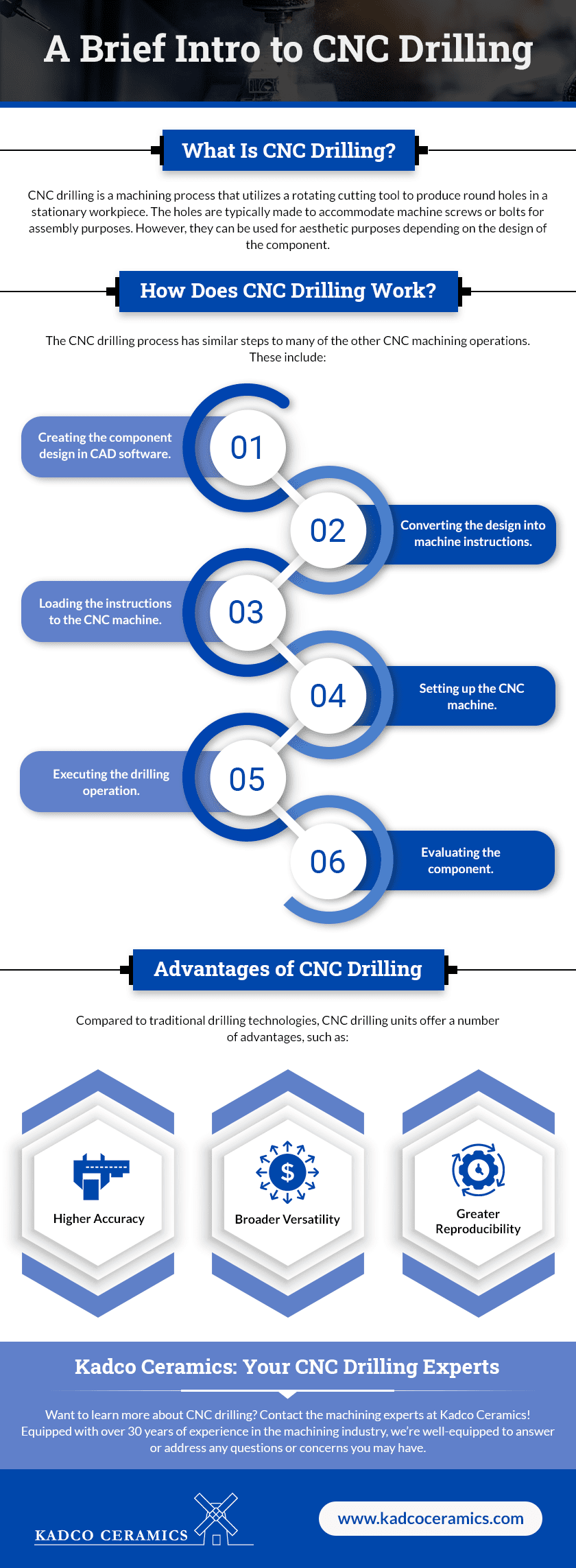

What Is CNC Drilling?

CNC drilling is a machining process that utilizes a rotating cutting tool to produce round holes in a stationary workpiece. The holes are typically made to accommodate machine screws or bolts for assembly purposes. However, they can be used for aesthetic purposes depending on the design of the component.

How Does CNC Drilling Work?

The CNC drilling process has similar steps to many of the other CNC machining operations. These include:

- Creating the component design in CAD software. The first step in producing a CNC drilled component is creating a digital design of it in CAD software.

- Converting the design into machine instructions. Once the component design is finalized, it needs to be converted into a language the CNC unit can understand. This step typically requires running the CAD design through CAM software to generate machine code.

- Loading the instructions to the CNC machine. When loaded to the CNC machine, the machine code controls how the CNC machine and tooling will move and operate throughout the drilling process.

- Setting up the CNC machine. Setting up the CNC machine generally involves installing the appropriate drill bit and securing the workpiece.

- Executing the drilling operation. Once the machine code is loaded and the machine is set up, the operator can initiate the drilling operation.

- Evaluating the component. After the drilling operation is finished, the operator evaluates the component for any errors or imperfections.

Advantages of CNC Drilling

Compared to traditional drilling technologies, CNC drilling units offer a number of advantages, such as:

- Higher accuracy. Drilling machines integrated with CNC technology can make holes that are accurate to t

he original design file within very tight margins.

he original design file within very tight margins. - Broader versatility. CNC drilling units can be used for a wide range of materials, from metal to plastic to wood. Additionally, since they can accommodate multiple drill bits, they can be utilized to produce a variety of holes.

- Greater reproducibility. Since CNC drilling units are computer-controlled, they are lessprone to error. As a result, manufacturers can achieve high consistency throughout a batch and between batches.

Kadco Ceramics: Your CNC Drilling Experts

Want to learn more about CNC drilling? Contact the machining experts at Kadco Ceramics! Equipped with over 30 years of experience in the machining industry, we’re well-equipped to answer or address any questions or concerns you may have.

Thomas Registered Supplier

Thomas Registered Supplier