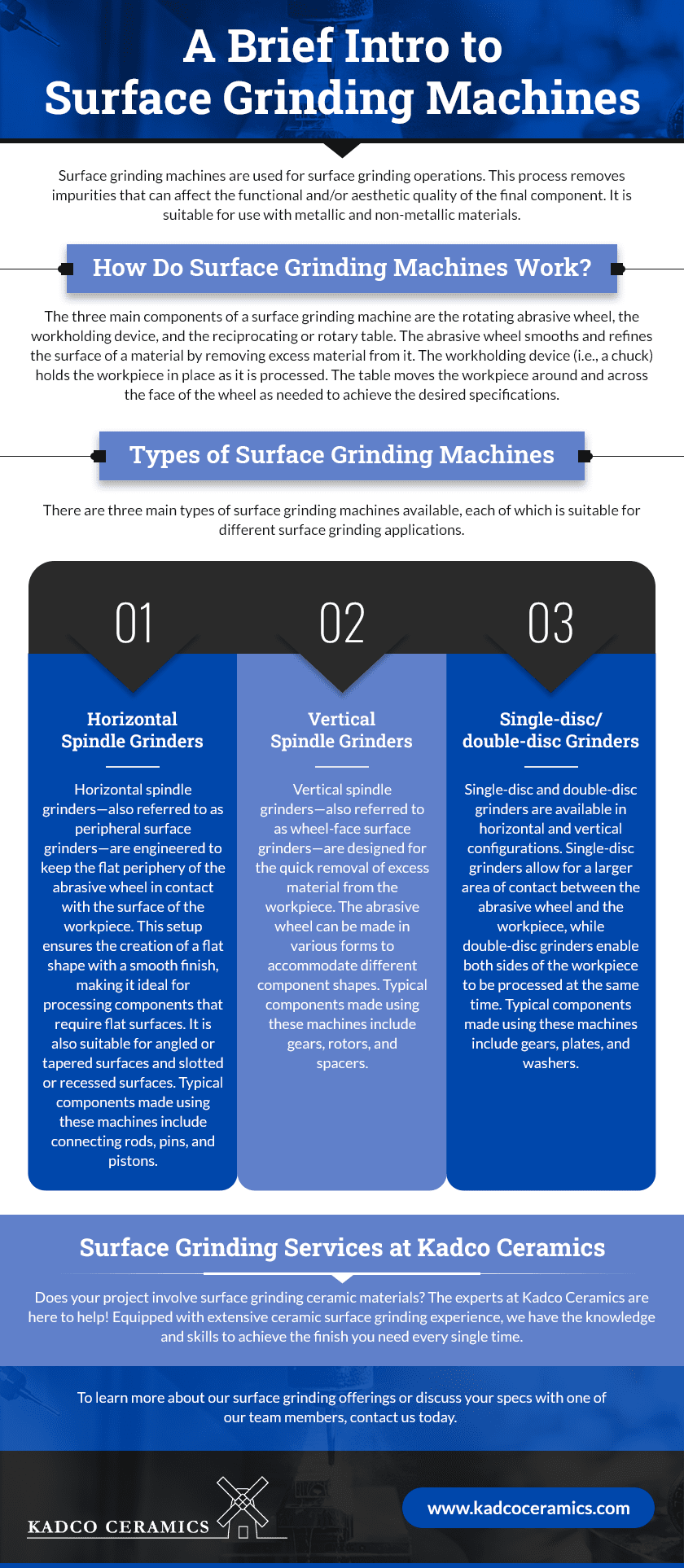

Surface grinding machines are used for surface grinding operations. This process removes impurities that can affect the functional and/or aesthetic quality of the final component. It is suitable for use with metallic and non-metallic materials.

How Do Surface Grinding Machines Work?

The three main components of a surface grinding machine are the rotating abrasive wheel, the workholding device, and the reciprocating or rotary table. The abrasive wheel smooths and refines the surface of a material by removing excess material from it. The workholding device (i.e., a chuck) holds the workpiece in place as it is processed. The table moves the workpiece around and across the face of the wheel as needed to achieve the desired specifications.

Types of Surface Grinding Machines

There are three main types of surface grinding machines available, each of which is suitable for different surface grinding applications.

- Horizontal spindle grinders. Horizontal spindle grinders—also referred to as peripheral surface grinders—are engineered to keep the flat periphery of the abrasive wheel in contact with the surface of the workpiece. This setup ensures the creation of a flat shape with a smooth finish, making it ideal for processing components that require flat surfaces. It is also suitable for angled or tapered surfaces and slotted or recessed surfaces. Typical components made using these machines include connecting rods, pins, and pistons.

- Vertical spindle grinders. Vertical spindle grinders—also referred to as wheel-face surface grinders—are designed for the quick removal of excess material from the workpiece. The abrasive wheel can be made in various forms to accommodate different component shapes. Typical components made using these machines include gears, rotors, and spacers.

- Single-disc/double-disc grinders. Single-disc and double-disc grinders are available in horizontal and vertical configurations. Single-disc grinders allow for a larger area of contact between the abrasive wheel and the workpiece, while double-disc grinders enable both sides of the workpiece to be processed at the same time. Typical components made using these machines include gears, plates, and washers.

Surface Grinding Services at Kadco Ceramics

Does your project involve surface grinding ceramic materials? The experts at Kadco Ceramics are here to help! Equipped with extensive ceramic surface grinding experience, we have the knowledge and skills to achieve the finish you need every single time. We offer a range of capabilities, including:

- Centerless end grinding

- Rotary grinding

- Grinding fixtures

To learn more about our surface grinding offerings or discuss your specs with one of our team members, contact us today.

Thomas Registered Supplier

Thomas Registered Supplier