Uses of Machined Piezoelectric Materials

The piezoelectric effect was discovered by brothers Pierre and Jacques Curie in 1880, and named after the Greek word piezein, that means to press or squeeze. They found that certain crystals were able to generate an electrical charge when mechanically loaded with tension or pressure. If exposed to an electric field, the same crystals would undergo a controlled deformation known as the inverse piezoelectric effect.

Compression and tension generate voltages of opposite polarity, so when compressed, the piezoelectric material decreases in volume and will have a voltage that has the same polarity as the material. When subjected to tension, the material will increase in volume and its voltage will be opposite to the polarity of the material.

Piezoelectric materials produce a voltage that is proportional to whatever mechanical pressure is applied.

When discussing piezoelectric ceramics and/or materials, it is important to know there are two types of material – crystals and ceramics. Most crystals occur naturally, while piezoelectric ceramics are manmade.

Piezoelectric Crystals

Naturally occurring piezoelectric crystals include:

- Quartz, the second-most common mineral in the Earth’s crust after feldspar.

- Berlinite, a rare transparent high-temperature mineral that has the same crystal structure as quartz.

- Topaz, a gemstone that forms in numerous colors.

- Tourmaline, classified as a semi-precious stone.

- Cane sugar used to manufacture granulated sugar.

- Rochelle salt, made from two of the first materials found to be piezoelectric: potassium sodium tartrate and monopotassium phosphate.

Manmade crystals include:

- Gallium orthophosphate, a colorless crystal with similar properties to quartz, but double the piezoelectric effect.

- Langasite, a piezoelectric crystal similar to quartz that was first produced about two decades ago.

Piezoelectric Ceramics

There are a number of piezoelectric ceramic types, including:

- Barium titanate

- Lead titanate

- Lead zirconate titanate (PZT)

- Lithium niobate

- Lithium tantalite

- Potassium niobate

- Sodium tungstate

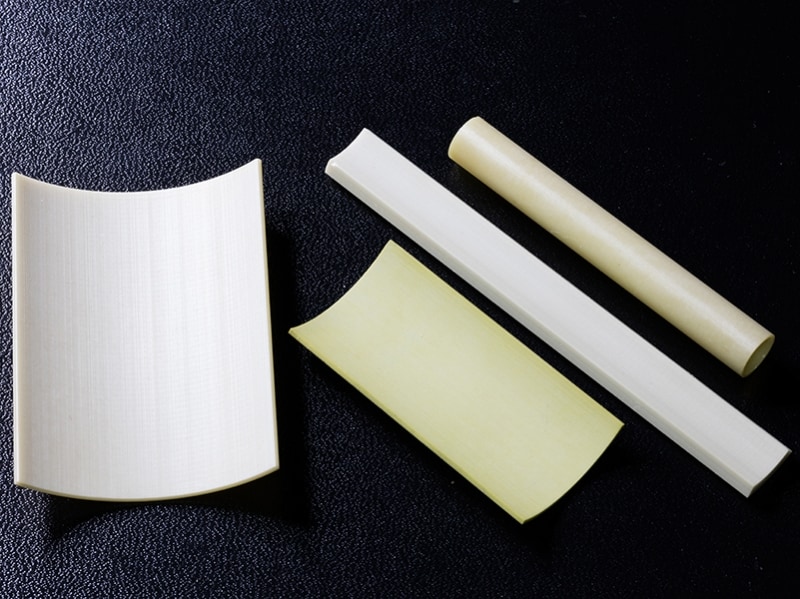

Piezoelectric systems manufactured today are primarily made from PZT, which is a mixture of lead zirconate and lead titanate crystals, or PZT and barium titanate. Making piezoelectric ceramics involves mixing the components in very specific proportions, then heating them to create a uniform powder. This powder is mixed with an organic binder before being formed into various structural elements.

Once the elements have been fired according to specified temperature and time requirements, they are shaped and trimmed, and electrodes are applied to surfaces where required. A variety of tools are used for this, but ID slicing saws are one of the most common and efficient solutions for machining piezoceramics.

Difference Between Ferroelectric and Piezoelectric Materials

While all ferroelectric materials are piezoelectric, not all piezoelectric materials are ferroelectric.

Ferroelectric and piezoelectric materials respond differently to electric fields, with the latter requiring a very high electric field. The field needed is so intense that the material achieves electric breakdown before polarization can occur. When the temperature is altered, however, the polarization of the crystal changes.

Conversely, ferroelectric materials are polarized spontaneously even though are piezoelectric. This is because of a lack of symmetry in the material caused by a crystal structure that is non-centrosymmetric. Ferroelectric materials also exhibit permanent magnetic behavior.

Piezoelectric material will generate electric potential if is subjected to some sort of mechanical energy. With ferroelectric material, when an external electric field is applied, polarization can be reversed.

Material classes for piezoelectric materials include organic, ceramic, and single crystals, while ferroelectric materials are only organic or ceramic in nature.

Although piezoelectric materials produce electricity, the quantity is too small to be usable.

Hard and Soft Piezoelectric Materials

Piezoelectric materials may be hard or soft, depending on the mobility of the charged or magnetized dipoles in the material. This directly affects polarization and depolarization.

PZT materials that are ferroelectrically hard can be subjected to very high mechanical and electrical stresses without affecting noticeable changes to their properties. They also have substantial advantages, including good stability, operating field strength, and high mechanical qualities.

Soft materials are fairly easy to polarize, even when field strengths are low. This gives them several advantages, such as:

- Large piezoelectric charge coefficients

- Moderate permittivity that enables storage of electrical energy

- High coupling factors

Piezoelectric Ceramics Applications

Piezoelectric ceramic materials have a wide range of applications, particularly for devices that are fuel-igniting, for solid-state batteries, and devices that are force-sensing. However, hard and soft materials have distinctly different uses.

Hard materials are particularly well suited to high-power acoustic applications. These include:

- Ultrasonic cleaning devices

- Tools used for drilling, bonding, and welding

- Ultrasonic processes

- Medical and surgical instruments

- Sonar technology

Soft piezoelectric ceramics are ideal for:

- Sensors, including conventional vibration detectors

- Ultrasonic transmitters and receivers

- Actuators used for nano-positioning or micro-positioning

- Object monitoring and identification

- Electro-acoustic applications, including microphones and sound transducers

- Sound pickups for musical instruments

Kadco Ceramics

Kadco Ceramics specializes in precision diamond machining and milling to produce components with complex geometries. Our equipment includes ID slicing saws and other machines which are ideal for machining and cutting piezoelectric ceramics. We have a great deal of experience machining piezoelectric materials for a variety of applications and industries.

If you work with piezoelectric materials, the professional team at Kadco Ceramics is ready to discuss your needs. Please contact us to see how we can help you.

Thomas Registered Supplier

Thomas Registered Supplier