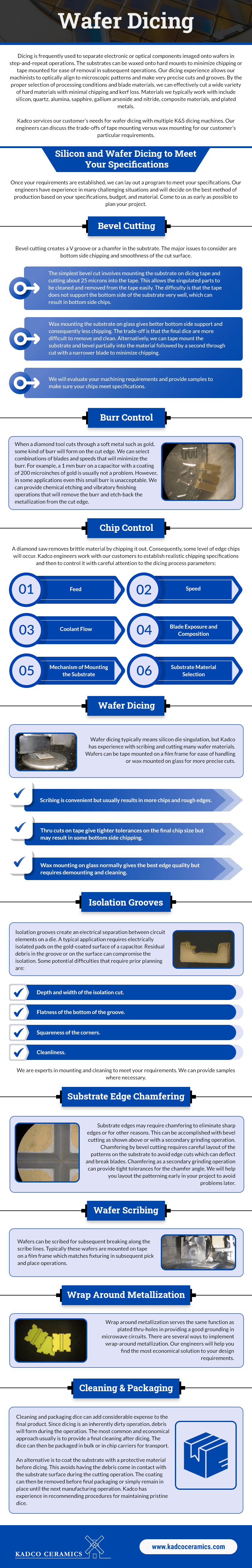

Dicing is frequently used to separate electronic or optical components imaged onto wafers in step-and-repeat operations. The substrates can be waxed onto hard mounts to minimize chipping or tape mounted for ease of removal in subsequent operations. Our dicing experience allows our machinists to optically align to microscopic patterns and make very precise cuts and grooves. By the proper selection of processing conditions and blade materials, we can effectively cut a wide variety of hard materials with minimal chipping and kerf loss. Materials we typically work with include silicon, quartz, alumina, sapphire, gallium arsenide and nitride, composite materials, and plated metals.

Dicing is frequently used to separate electronic or optical components imaged onto wafers in step-and-repeat operations. The substrates can be waxed onto hard mounts to minimize chipping or tape mounted for ease of removal in subsequent operations. Our dicing experience allows our machinists to optically align to microscopic patterns and make very precise cuts and grooves. By the proper selection of processing conditions and blade materials, we can effectively cut a wide variety of hard materials with minimal chipping and kerf loss. Materials we typically work with include silicon, quartz, alumina, sapphire, gallium arsenide and nitride, composite materials, and plated metals.

Kadco services our customer’s needs for wafer dicing with multiple K&S dicing machines. Our engineers can discuss the trade-offs of tape mounting versus wax mounting for our customer’s particular requirements.

Silicon and Wafer Dicing to Meet Your Specifications

Once your requirements are established, we can lay out a program to meet your specifications. Our engineers have experience in many challenging situations and will decide on the best method of production based on your specifications, budget, and material. Come to us as early as possible to plan your project.

Bevel Cutting

Bevel cutting creates a V groove or a chamfer in the substrate. The major issues to consider are bottom side chipping and smoothness of the cut surface.

- The simplest bevel cut involves mounting the substrate on dicing tape and cutting about 25 microns into the tape. This allows the singulated parts to be cleaned and removed from the tape easily. The difficulty is that the tape does not support the bottom side of the substrate very well, which can result in bottom side chips.

- Wax mounting the substrate on glass gives better bottom side support and consequently less chipping. The trade-off is that the final dice are more difficult to remove and clean. Alternatively, we can tape mount the substrate and bevel partially into the material followed by a second through cut with a narrower blade to minimize chipping.

- We will evaluate your machining requirements and provide samples to make sure your chips meet specifications.

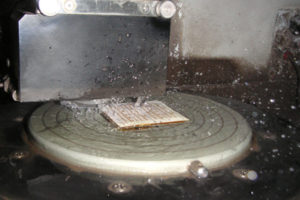

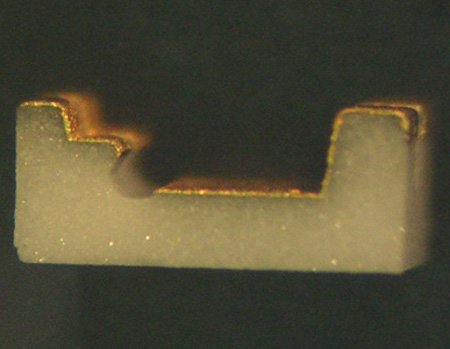

Burr Control

When a diamond tool cuts through a soft metal such as gold, some kind of burr will form on the cut edge. We can select combinations of blades and speeds that will minimize the burr. For example, a 1 mm burr on a capacitor with a coating of 200 microinches of gold is usually not a problem. However, in some applications even this small burr is unacceptable. We can provide chemical etching and vibratory finishing operations that will remove the burr and etch-back the metallization from the cut edge.

Chip Control

A diamond saw removes brittle material by chipping it out. Consequently, some level of edge chips will occur. Kadco engineers work with our customers to establish realistic chipping specifications and then to control it with careful attention to the dicing process parameters:

- Feed

- Speed

- Coolant flow

- Blade exposure and composition

- Mechanism of mounting the substrate

- Substrate material selection

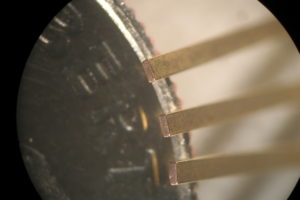

Wafer Dicing

Wafer dicing typically means silicon die singulation, but Kadco has experience with scribing and cutting many wafer materials. Wafers can be tape mounted on a film frame for ease of handling or wax mounted on glass for more precise cuts.

- Scribing is convenient but usually results in more chips and rough edges.

- Thru cuts on tape give tighter tolerances on the final chip size but may result in some bottom side chipping.

- Wax mounting on glass normally gives the best edge quality but requires demounting and cleaning

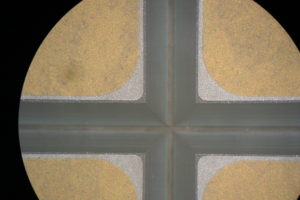

Isolation Grooves

Isolation grooves create an electrical separation between circuit elements on a die. A typical application requires electrically isolated pads on the gold-coated surface of a capacitor. Residual debris in the groove or on the surface can compromise the isolation. Some potential difficulties that require prior planning are

- Depth and width of the isolation cut

- Flatness of the bottom of the groove

- Squareness of the corners

- Cleanliness

We are experts in mounting and cleaning to meet your requirements. We can provide samples where necessary.

Substrate Edge Chamfering

Substrate edges may require chamfering to eliminate sharp edges or for other reasons. This can be accomplished with bevel cutting as shown above or with a secondary grinding operation. Chamfering by bevel cutting requires careful layout of the patterns on the substrate to avoid edge cuts which can deflect and break blades. Chamfering as a secondary grinding operation can provide tight tolerances for the chamfer angle. We will help you layout the patterning early in your project to avoid problems later.

Wafer Scribing

Wafers can be scribed for subsequent breaking along the scribe lines. Typically these wafers are mounted on tape on a film frame which matches fixturing in subsequent pick and place operations.

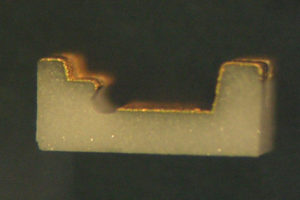

Wrap Around Metallization

Wrap around metallization serves the same function as plated thru-holes in providing a good grounding in microwave circuits. There are several ways to implement wrap-around metallization. Our engineers will help you find the most economical solution to your design requirements.

Cleaning & Packaging

Cleaning and packaging dice can add considerable expense to the final product. Since dicing is an inherently dirty operation, debris will form during the operation. The most common and economical approach usually is to provide a final cleaning after dicing. The dice can then be packaged in bulk or in chip carriers for transport.

An alternative is to coat the substrate with a protective material before dicing. This avoids having the debris come in contact with the substrate surface during the cutting operation. The coating can then be removed before final packaging or simply remain in place until the next manufacturing operation. Kadco has experience in recommending procedures for maintaining pristine dice.

Thomas Registered Supplier

Thomas Registered Supplier