Kadco Ceramics is dedicated to the precision diamond machining of hard materials into intricate shapes. Since 1982 Kadco has focused on providing engineering assistance and production solutions to a broad spectrum of industrial and R&D needs. Let Kadco’s experience help solve your engineering problems and provide cost-effective answers to your production requirements.

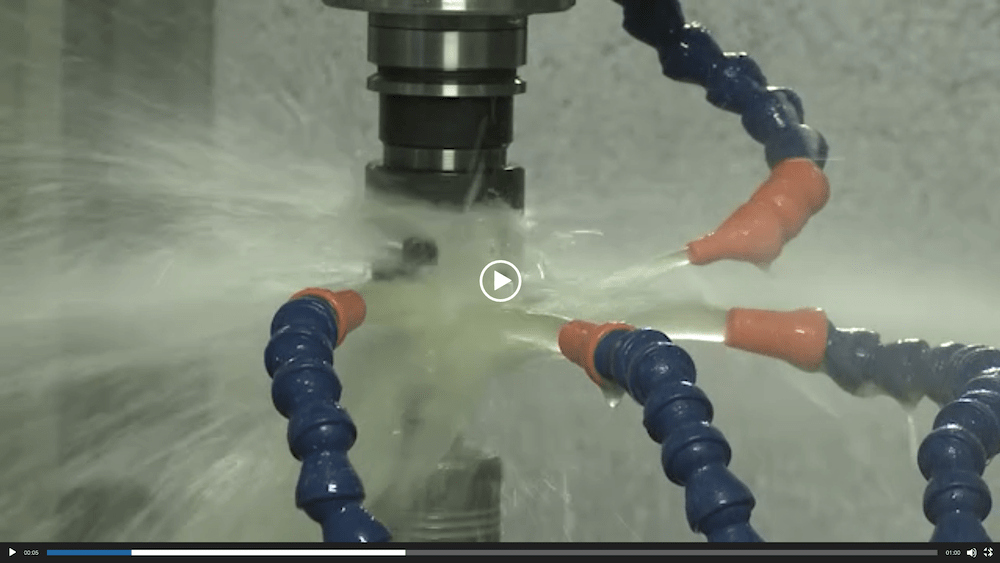

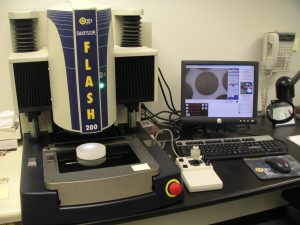

Kadco Ceramics specializes in four areas of diamond machining: milling, grinding, ID slicing, and dicing. All of these utilize state of the art CNC equipment guided by the expertise of our professional machining staff. Our diamond milling and grinding departments, illustrated by our logo, perform primarily diamond machining on a wide range of difficult materials. This includes challenging combinations such as copper traces on ceramic substrates and tight tolerances on the radius of curvature for piezoceramic lenses.

ID (internal diameter) slicing is frequently a cost-effective solution for preparing large quantities of very thin components. We are always looking to extend our experience in ID slicing to unusual materials. We have had a recent experience with thin sections of pyrolytic graphite, ferrites, piezoceramics, and Macor.

Our dicing experience includes not only the singulation of silicon wafers but operations such as creating grooves in ceramics and minimizing burrs on plated electronic components. If our engineering department can’t solve your problem, we will be happy to refer you to someone who can from our extensive list of customers and vendors.

Our Goal

Our goal is to satisfy our customer’s needs through quality, delivery, and price. This is accomplished through communication between the customer and Kadco. The more we know about your needs, the better we can provide cost-effective solutions. This allows us to provide material selection and assist you through basic design and engineering problems. Tell us what your needs are and we will assist in every practical way. Should the job not be suited for Kadco, we will direct you to the proper source.

Our goal is to satisfy our customer’s needs through quality, delivery, and price. This is accomplished through communication between the customer and Kadco. The more we know about your needs, the better we can provide cost-effective solutions. This allows us to provide material selection and assist you through basic design and engineering problems. Tell us what your needs are and we will assist in every practical way. Should the job not be suited for Kadco, we will direct you to the proper source.

Thomas Registered Supplier

Thomas Registered Supplier